Automation with you in mind.

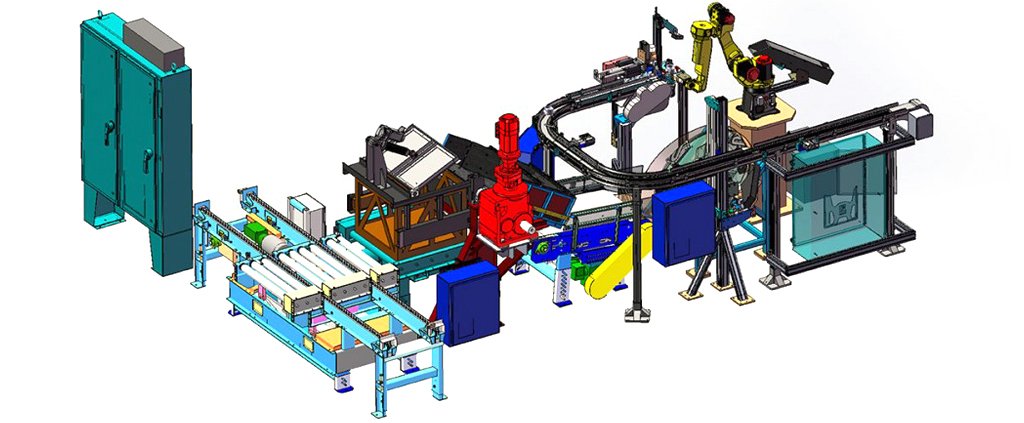

Our experienced machine building and integration technicians are capable of providing a wide variety of systems from specialized intricate turnkey to simple, lean, operator-assisted machines.

At U.S. Automation all of our automated systems are designed and built in-house to control cost and maintain quality. Each design is presented to our customer for approval prior to any material being fabricated. Once the machine has been built a run-off is conducted at our facility to ensure complete customer satisfaction. We then set up the machine at your facility and perform another run-off. These steps help ensure that every customer receives the highest quality equipment and that each machine has been built to all specifications and has met all requirements.

Conveying / Transfer Systems

U.S. Automation designs and builds complex and simple automated transfer and conveying systems that can be designed to assemble components around your existing work cells and convey components to the next process.

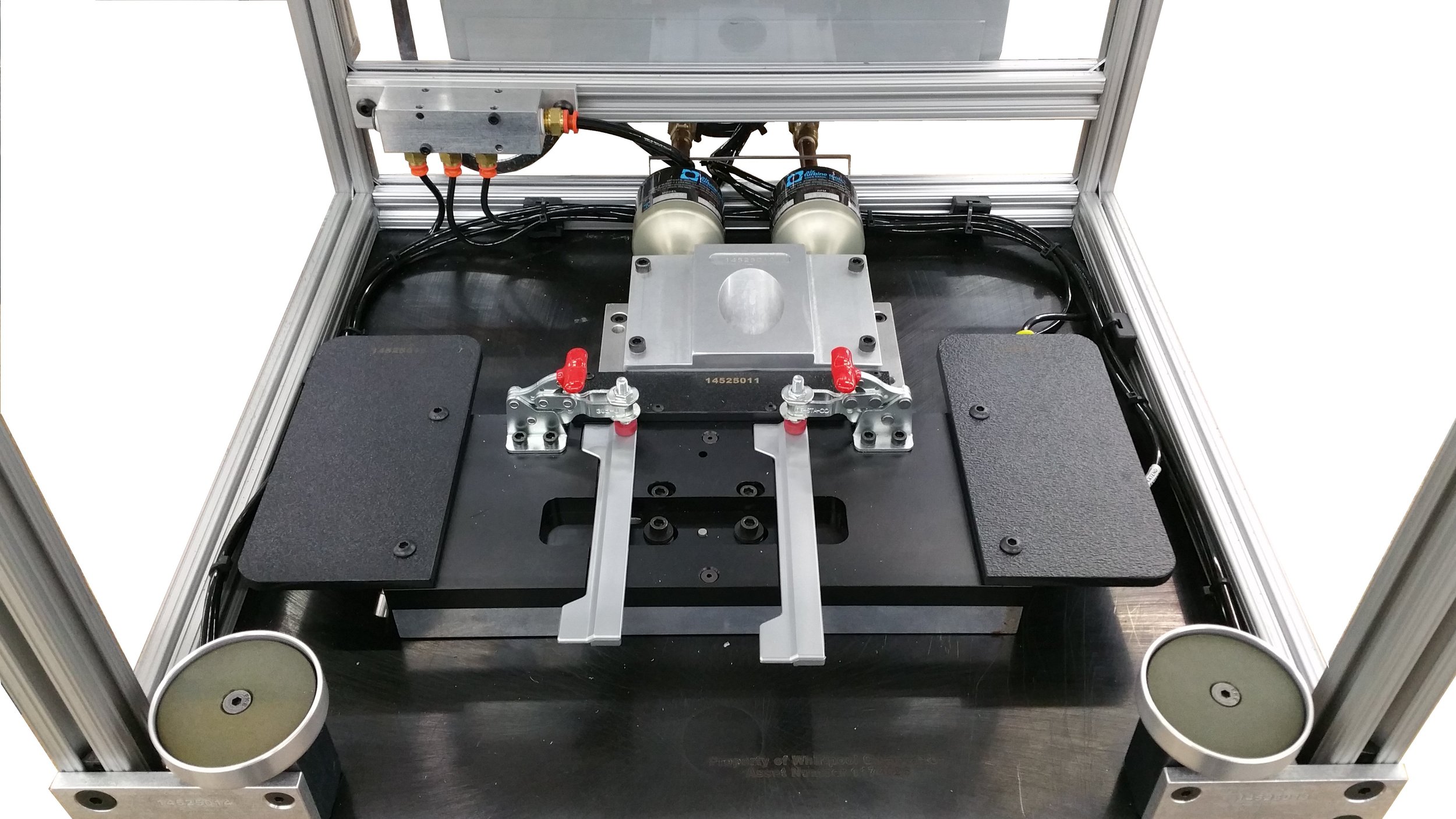

Inspection / Test Systems

U.S. Automation offers and integrates a wide range of inspection systems including contact and non-contact. Our systems can verify marking on a component, presence of the components, height and depth and flatness, as well as barcode reading and leak testing. We utilize high speed vision, laser inspection, depth and height sensors, gage plate inspection and a variety of other components in our automated inspection / test systems.

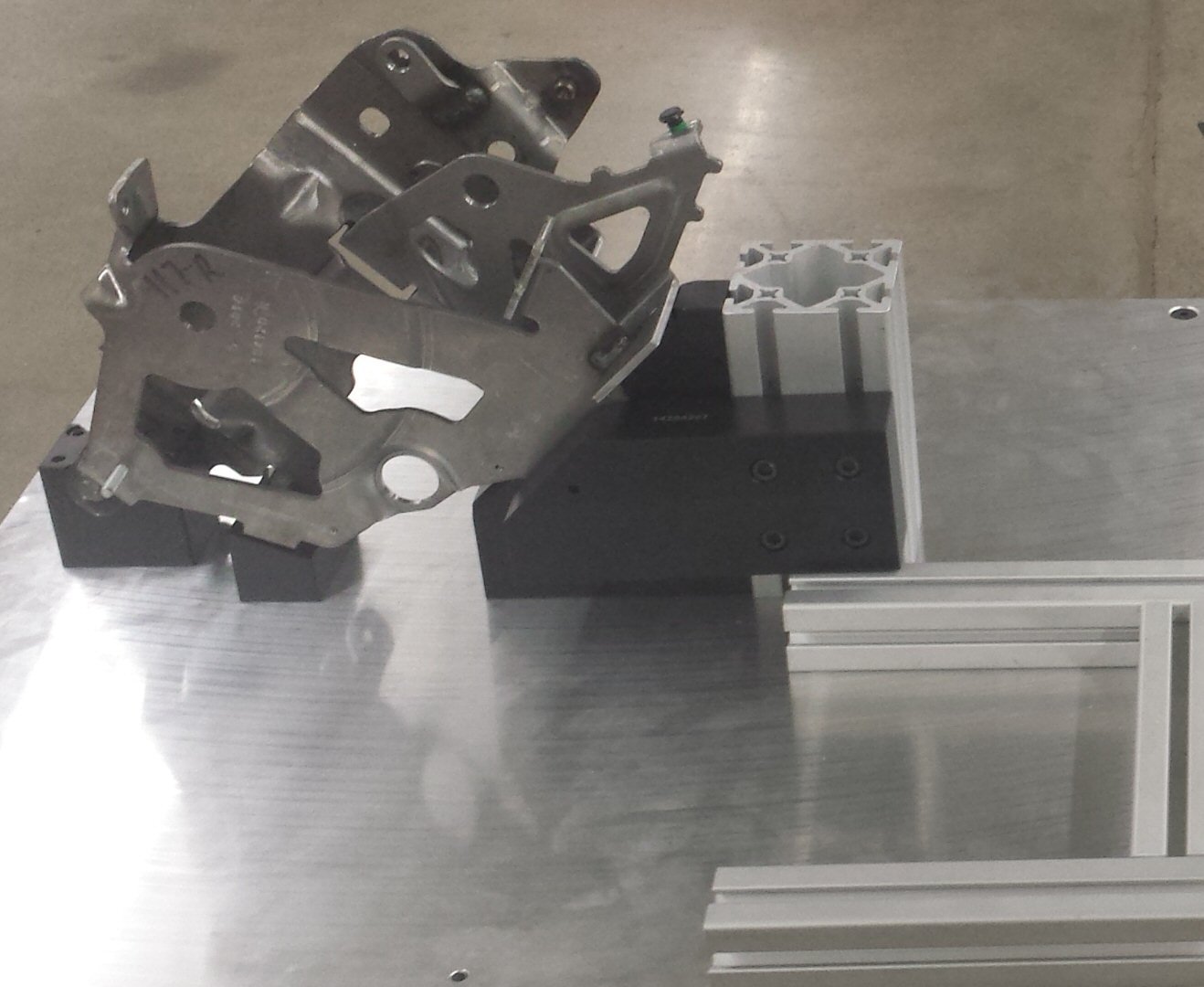

Lean Systems

U.S. Automation builds lean systems that assist the operator in performing various tasks. Lean systems can include marking, screw driving, torquing, vision inspection, gauging and many other applications.

Part Marking Systems

U.S. Automation can design and build systems to meet your specific part marking needs. Whether you need laser marking, pin stamping, or label printing we can integrate the proper equipment to create a system to meet your requirements.

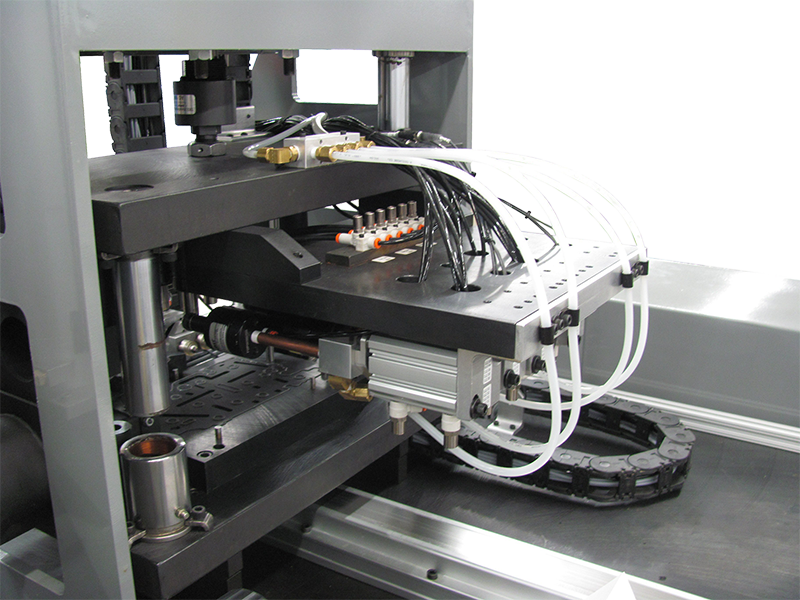

Presses

U.S. Automation can utilize your new or existing press to automate your current manual process to improve efficiency and increase your end quality. Our experienced team of engineers can design, manufacture, and integrate tooling to accommodate your pressing needs. Automated shuttle features move the component into the press, form it, and return it back to the operator.

Presses include:

Punch Presses

Stamping Presses

Flywheel Presses

Hydraulic Presses

Rotary Systems

At U.S. Automation we utilize our many years of experience to produce high quality and reliable automated rotary systems to meet your specific requirements. We can build your automated rotary system to feed, place, assemble, and inspect your components. Our systems can also be built to cut, print, weld, drill & tap and much more.

Robotic Systems / EOAT

U.S. Automation builds and integrates robotic systems for your precise and high-speed applications. We offer robotic systems to handle part placement, stacking, machining, inspection, welding, and much more. We can integrate robots from Epson, Yushin, Yamaha, Fanuc, ABB and others.

Ultrasonic Welding Systems

U.S. Automation offers and integrates a wide range of inspection systems including contact and non-contact. Our systems can verify marking on a component, presence of the components, height and depth, and flatness, as well as barcode reading and leak testing. We utilize high-speed vision, laser inspection, depth and height sensors, gage plate inspection, and a variety of other components in our automated inspection/test systems.

Get started with your project

Because each project is custom, each price is custom. Complete the form below to obtain a quote for your next customized building project. We’ll be happy to follow up to discuss your specific needs and the scope of your automation requirements.